The Texas Manufacturing Assistance Center (TMAC) specializes in providing advanced manufacturing technology services aimed at enhancing productivity, efficiency, and competitiveness for businesses. With expertise across various areas such as automation, 3D modeling, 3D printing, prototyping, cloud computing, augmented reality, big data analytics, cybersecurity, IIoT, and software integration, TMAC empowers organizations to leverage cutting-edge technologies for strategic advantage.

Our services encompass comprehensive assessments, strategy development, implementation, and training, tailored to the specific needs and goals of each client. Whether it’s optimizing production processes, improving product design and development, enhancing supply chain management, or bolstering cybersecurity measures, our Business Advisors offer holistic solutions to drive innovation and growth.

Through a combination of industry experience, technical proficiency, and a collaborative approach, our team enables businesses to harness the full potential of advanced manufacturing technologies, positioning them for sustained success in an increasingly competitive marketplace.

Technologies

3D Modeling / Simulation

3D modeling and simulation allow manufacturers to visualize and test product designs before physical prototyping, reducing development time and costs. Discover more in the video.

3D Printing

3D printing enables the creation of complex parts and prototypes directly from digital models, offering flexibility and customization. Learn more through the video.

Augmented Reality

Augmented reality overlays digital information onto the real world, offering enhanced training, maintenance, and design visualization capabilities. Watch the video for a deeper understanding.

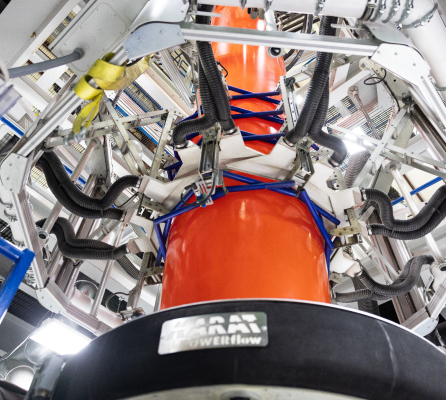

Automation / Robotics

Automation and robotics streamline manufacturing processes by replacing manual labor with automated machinery, improving efficiency and consistency. Watch the video for more insights.

Big Data

Big data analytics harness large volumes of data to uncover insights, optimize processes, and make data-driven decisions, enhancing efficiency and competitiveness. Delve deeper into the topic in the video.

Cloud

Cloud computing provides scalable and accessible storage and computing resources, facilitating collaboration and data management. Explore further in the video.

Cybersecurity

Cybersecurity measures protect manufacturing systems and data from cyber threats, ensuring operational continuity and safeguarding sensitive information. Check out the video for more information.

IIoT (Industrial Internet of Things)

IIoT connects machinery, sensors, and devices to gather and analyze data, enabling predictive maintenance, process optimization, and real-time monitoring. Learn more in the video.

Prototyping

Prototyping involves creating initial versions of products to test and refine designs before full-scale production, facilitating innovation and reducing risks. View the video to discover more about how NIST MEP can assist you.

Software Integration

Software integration integrates various software systems within the manufacturing environment, improving communication, data sharing, and overall efficiency. Explore further in the video.